TOTAL PACKAGING SOLUTIONS

Industrial Power Sieve

In high-speed packaging operations, product clumping is a common problem—particularly with sticky, moisture-sensitive, or irregularly shaped foods. Whether it’s grated cheese, sultanas, legumes, or frozen vegetables, these blockages can slow down weighers, jam filling heads, and throw off accuracy.

That’s why the ADM‑VH1 Industrial Power Sieve is a critical component in our turnkey food packaging systems. Acting as an inline product de-clumper, it’s placed directly after storage hoppers or conveyors to condition product flow before it reaches sensitive downstream equipment like multihead weighers, VFFS machines, or tray sealers.

As part of an ADM-designed line, the VH1 helps you reduce operator intervention, minimise weighing errors, and keep throughput moving—ensuring a stable, hygienic, and efficient system.

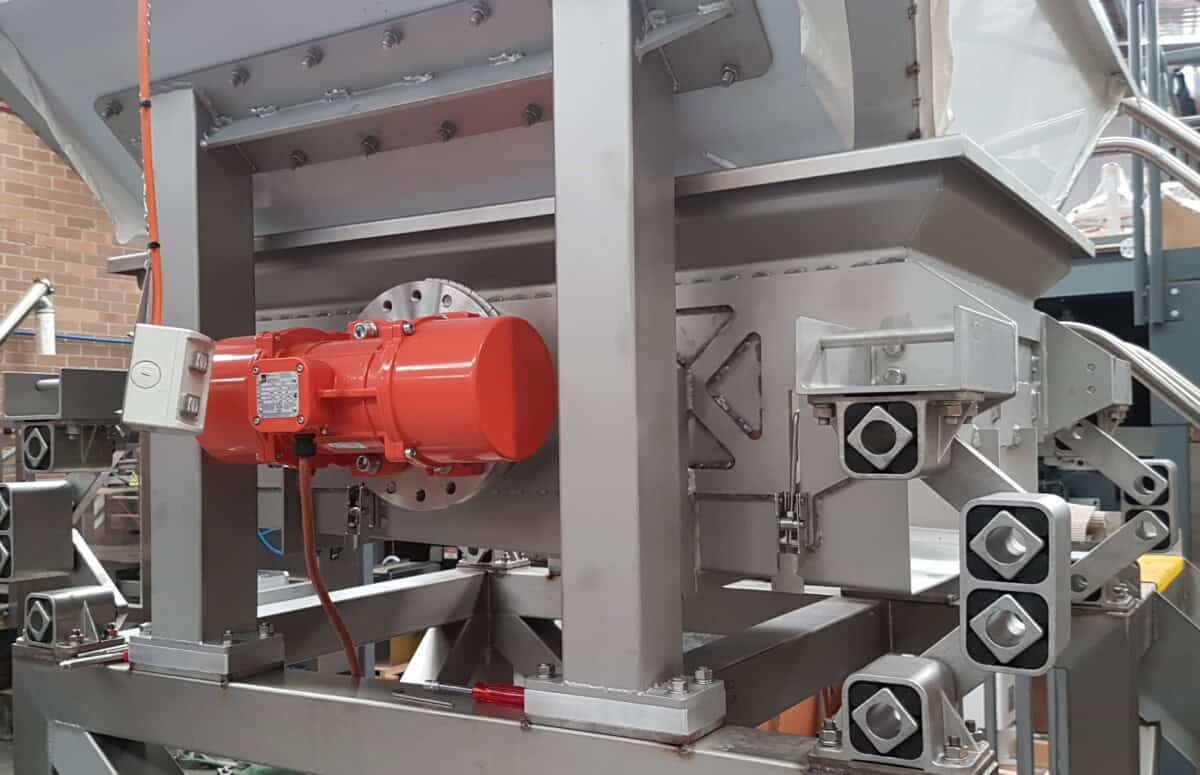

The ADM-VH1 200kg Power Sieve is a compact, heavy-duty food-grade sieve and clump breaker built for integration into dry food handling, dairy, snack, or frozen product lines.

At its core, the VH1 uses a rotary agitation system—featuring intense agitation of the the product type that actively disrupts product clumps without degrading delicate material. This makes it ideal for use with soft or sticky items like sultanas, grated cheese, legumes, frozen proteins, and coated granules.

The unit is constructed entirely from food-grade stainless steel with smooth welds and hygienic design principles. Its compact footprint allows it to be mounted directly under hoppers, silos, or bulk storage bins, and it can be easily integrated with ADM conveyors, weighers, and form-fill-seal machines as part of a complete turnkey solution.

An optional variable-speed motor allows adjustment of agitation intensity to match different products and flow rates. Access panels or quick-release components are provided for easy cleaning and maintenance, making the VH1 suitable for allergen-sensitive environments or frequent product changeovers.

- Durable reinforced stainless steel construction

- Interchangeable mesh sizes

- High/low sensor for fast and slow feeds

- Up to 5G acceleration to break up products

- Free standing or mountable to systems

- Easy access for cleaning

- Small footprint

- Compatible with dry food, cheese processing lines, and frozen food handling

The VH1 is ideal for manufacturers needing an inline product conditioning system or automated de-clumper in packaging operations. Common use cases include:

Shredded and grated cheese (e.g. mozzarella, cheddar, parmesan)

Sticky dried fruits (e.g. sultanas, raisins, dates)

Legumes and pulses (e.g. lentils, beans, chickpeas)

Frozen diced meat or vegetables

Coated snack foods (e.g. honey-roasted nuts, seasoned popcorn)

Sticky powders or granules prone to clumping in bulk

Detailed Application Example: Clumped Sultanas in Snack

Sultanas are a naturally sticky product. When stored in bulk bins or transferred through holding hoppers, they tend to clump together due to residual moisture, sugar content, and compression—especially in warmer environments or during transit.

Without proper separation, these clumps disrupt downstream filling equipment, cause weighing inaccuracies, and lead to jams or product bridging at the infeed. In high-speed snack or baking lines, this can result in underfilled packs, downtime, or product giveaway.

To address this, the ADM‑VH1 Industrial Power Sieve is positioned directly after the bulk hopper or metering bin and just before the ADM conveyor feeding the multihead weigher or volumetric filler. As sultanas are released, the VH1 uses gentle mechanical agitation to disrupt clusters without damaging the fruit—returning the product to a free-flowing, even consistency.

From there, the product moves smoothly into the weighing or filling system for precise portioning into stand-up pouches, sachets, tubs, or pillow bags.

Why the VH1 Works for Sultanas:

-

Breaks up sticky clumps without crushing or bruising the product

-

Improves flow consistency into weighers, hoppers, and fillers

-

Reduces jams and line stoppages caused by compacted clusters

-

Minimises manual clearing and handling—improving hygiene and efficiency

-

Compatible with ADM turnkey snack and dried fruit packaging systems

-

Built with food-grade stainless steel and ready for washdown in allergen-sensitive zones

Specifications

| Model | ADM-VH1 |

| Hopper opening size | 1400 x 1400 mm |

| Capacity | 200kg power sieve (sultanas), 50kg lower feed hopper |

| Feed rate | 60kg/min max (sultanas) |

| Speed | 1800 rpm max |

| Power Supply | 415V, 50Hz, 1.1kW |

| Footprint inc platform | 2900L x 2200W x 2400H mm |