Packaging Machinery

Metal Detectors

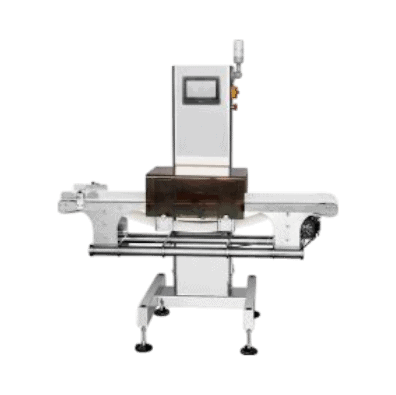

ADM Packaging Automation offer reliable Metal Detectors used for inspection of process lines and end of line packaging. The metal detectors are designed to detect ferrous and non ferrous contaminants. With a robust design to reduce vibration, the metal detectors can offer the best detection as specified. When metal is detected, these units offer output signals to activate for optional alarms, stop the conveyor, reject chute, air blast or light signals.

Many metal detectors struggle with metalized film, this is typically aluminium foil used in the packaging as an oxygen barrier. The ADM-MDF series metal detector is specifically designed for foil applications. Common products include, chocolate, coffee, jerky and nuts.

- Stainless steel construction

- Detect iron, stainless steel

- Digital display

- Adjustable product effect

- Teach in function for products

- Store up to 99 settings

- Adjustable sensitivity

Specifications

| Model | ADM-MDF24 |

| Detecting method | Electromagnetic induction |

| Passing height | 50-150mm |

| Passing width | 240mm |

| Precision | Fe ⌀2mm, SS ⌀2mm |

| Power | 240V 50Hz |

| Alarm method | Sound and light alarm, stop automatically |

| Device of defective good | Air-flow, shaking bars, dropping, etc (selectable) |

| Dimension | 1450L x 850W x 1620H |

| Weight | 160kg |