Total packaging solutions for the Horticulture industry

Horticulture Packaging Machinery

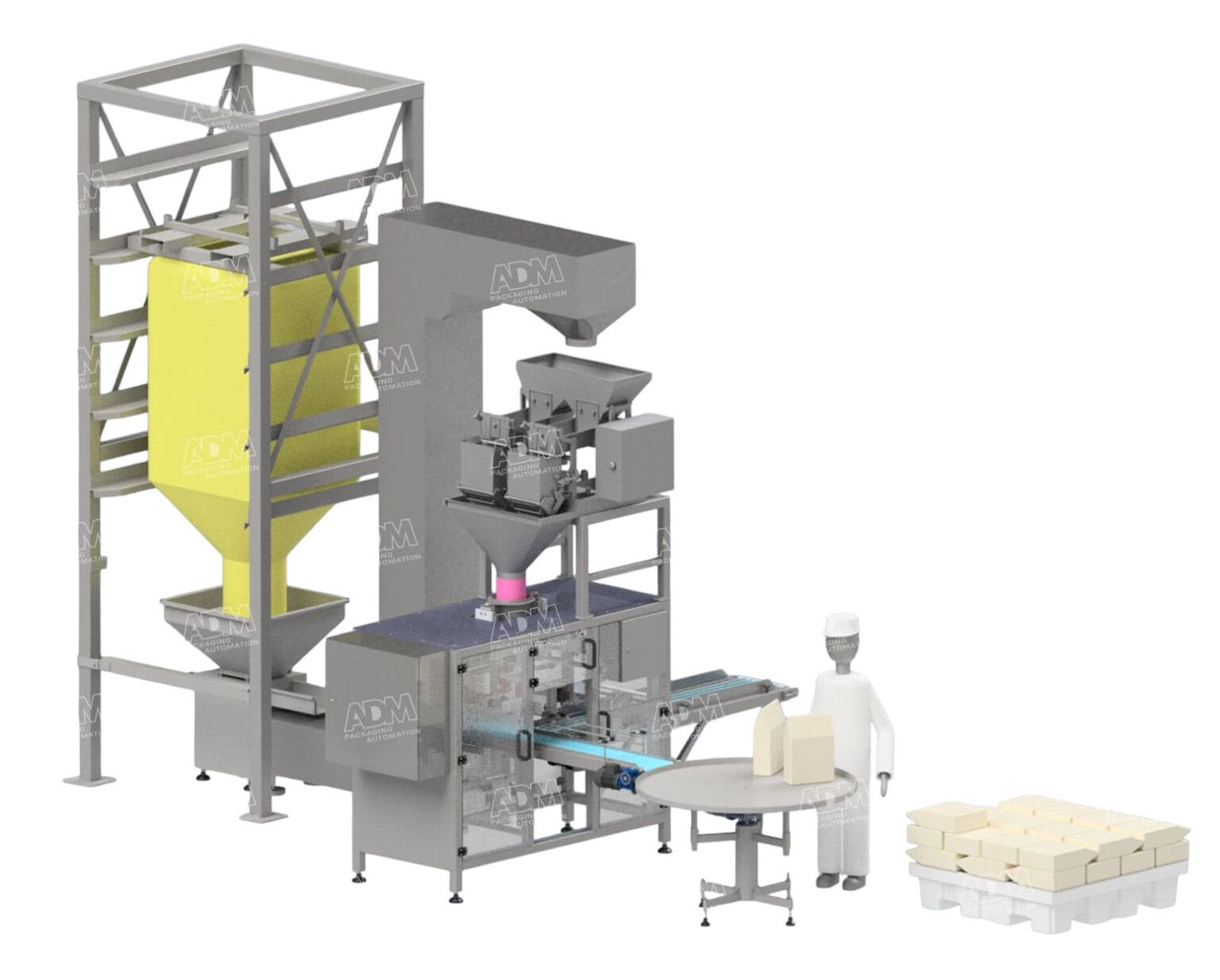

Home gardening is growing in popularity. Whether for a farm, a large garden or a small balcony, customers can choose from a range of potting mixes, composts and fertilisers. Producers and manufacturers have to efficiently package and deliver a quality end product. ADM can supply a complete line solution involving the conveying, weighing, filling and sealing of your product, whether it is a potting mix, pellet fertiliser or powdered product like blood-and-bone.

ADM have a number of machines that will package gardening products, whether you want a premade bag such as a doy pouch or gusseted quad seal bag or want to use a rewind film on a Vertical Fill Form and Seal (VFFS) machine.

At ADM we specifically engineered and built the ADM-XD20. Compact in size and loaded with automated process motion, it packs the large demanding premade bags that many machines fail to do. It performs best with bags that need better handling for the effects of large opening, high filling rate, minimal bridging filling demands and rigorous settling. It can adapt to various styles of premade pouches up to 360mm wide and 500mm long, its two head weighing system can deliver up to 15L (or 10kg) of gardening product with ease.

ADM can customise and add dust extraction, product settling systems, blockage detection or printing and labelling. We will provide technical engineering drawings for your line as well as professional electrical, and pneumatic schematics.

Our in-house engineers will work with your floor plans to integrate existing systems and application requirements to customise your packaging line. Whether you need an entry level machine or a fully automated production line, ADM Packaging Automation are the experts in supplying packaging equipment to improve efficiency, increase productivity and deliver cost savings to your production line.

Individual Equipment

At ADM we specifically engineered and built the ADM-XD20. Compact in size and loaded with automated process motion, it packs the large demanding premade bags that many machines fail to do. It performs best with bags that need better handling for the effects of large opening, high filling rate, minimal bridging filling demands and rigorous settling. It can adapt to various styles of premade pouches up to 360mm wide and 500mm long, its two head weighing system can deliver up to 15L (or 10kg) of gardening product with ease.

ADM can customise and add dust extraction, product settling systems, blockage detection or printing and labelling. We will provide technical engineering drawings for your line as well as professional electrical, and pneumatic schematics.

Our in-house engineers will work with your floor plans to integrate existing systems and application requirements to customise your packaging line. Whether you need an entry level machine or a fully automated production line, ADM Packaging Automation are the experts in supplying packaging equipment to improve efficiency, increase productivity and deliver cost savings to your production line.

Contact us today to see how our innovative packaging machinery can handle all your dairy packaging needs.

ADM-DP31 Coffee Machine

The ADM DP31, designed and built in Melbourne—Australia’s coffee capital—fully automates your coffee packaging line. Featured at the Melbourne International Coffee Expo (MICE), it weighs and doses coffee, opens bags, fills, seals, and prints best-before dates—all in one machine.

It handles 250g, 500g, and 1kg bags with one-way valves, using suction cups to open paper or plastic bags and high powered vibration to settle the coffee beans or ground coffee in the bag. A quick 5-minute changeover allows for different bag sizes.

Optional features include dust extraction for ground coffee and nitrogen flushing for freshness. Combined with a product transfer and check weighing system, the ADDP31 is a complete coffee packaging solution.

ADM-DP31 Coffee Machine

The ADM DP31, designed and built in Melbourne—Australia’s coffee capital—fully automates your coffee packaging line. Featured at the Melbourne International Coffee Expo (MICE), it weighs and doses coffee, opens bags, fills, seals, and prints best-before dates—all in one machine.

It handles 250g, 500g, and 1kg bags with one-way valves, using suction cups to open paper or plastic bags and high powered vibration to settle the coffee beans or ground coffee in the bag. A quick 5-minute changeover allows for different bag sizes.

Optional features include dust extraction for ground coffee and nitrogen flushing for freshness. Combined with a product transfer and check weighing system, the ADDP31 is a complete coffee packaging solution.