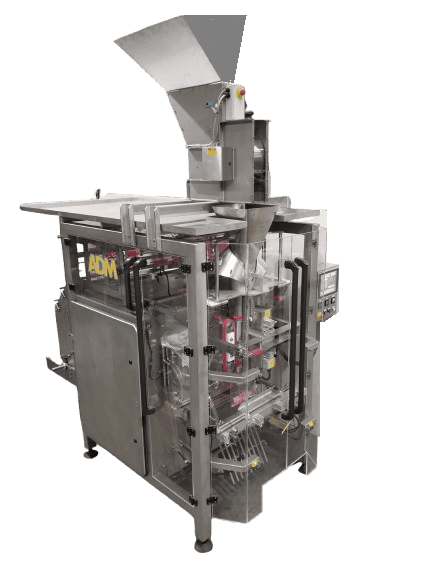

ADM-XL Series VFFS for Animal and Gardening Products

The ADM-XL Series is designed, engineered, and built in Australia at out Thomastown (VIC) facility, it’s our industrial-scale Vertical Form Fill Seal (VFFS) line-engineered to serve heavy-duty packaging applications with unmatched consistency and durability.

Where models like the C and i Series focus on speed and precision for lighter formats, the XL Series is designed to handle extra-large and high-weight bagging tasks. Its robust frame and intermittent motion sealing provide the structural strength and seal integrity needed for bulk animal feeds, seeds, fertilisers, soils, and gardening supplies.

Embedded at the core of turnkey packaging systems, the XL Series seamlessly aligns with heavy-capacity feeders, weighers, conveyors, inspection stations, and palletisers. The result is a streamlined, high-throughput workflow delivering strength, reliability, and unwavering performance for even the most demanding volume requirements.

Like the rest of the ADM VFFS line, the XL Series is built locally, offering full adaptability to bag size, product density, and layout constraints-ensuring every machine meets global standards with responsive Australian engineering and support.

The ADM-XL Series Vertical Form Fill Seal Machines are engineered for extra-large, high-capacity packaging where strength, seal integrity, and throughput are critical. Designed and built at ADM’s Thomastown facility, the XL Series combines heavy-duty stainless-steel construction, precision film handling, and reinforced sealing systems to deliver reliable performance for oversized and high-weight bags.

Intermittent motion sealing technology allows the XL Series to pause film for each seal cycle, providing maximum dwell time for strong, consistent seals – even on heavy-gauge laminated or woven polypropylene bags.

Key advantages of the XL Series:

- Handles very large and heavy bags – ideal for agriculture, gardening, and stock feed markets

- Strong, reliable seals on thick or multi-layer films

- Customisable forming sets for a wide range of bulk product sizes and bag styles

- Integration-ready with bulk infeed, weighing, dust control, and palletising equipment

- Compatibility with laminated, recyclable mono-material, and compostable films

Typical product range:

- Animal stock feeds and supplements

- Bulk seeds, pulses, and grains

- Fertilizers and soil enhancers

- Gardening and landscaping products (mulch, soil, potting mix)

Features

- MADE IN AUSTRALIA

- Pack dry products

- Servo Motor Controlled Film Pull Belts

- Servo Motor Controlled Jaw Seal Actuation

- Touch Screen Operator Interface

- PLC - Based Control System

- Ethernet/IP based system

- Ethernet/IP Central Control system

- Pneumatics Advanced Integration

- Vacuum Belt Drive

- Pneumatic balancing

- Safety Guarding and Interlocks to AS4024

Optional Elements

- Pillow bags

- Gusseted device

- Block Bottom bags

- Nitrogen gas flush systems

- Vacuum assist units

- Static eliminators

- Vacuum seal

- Impulse seal

Built for oversized and heavy-duty packaging, the ADM-XL Series is ideal for bulk goods where weight, size, and handling demand extra durability and sealing power.

Common applications include:

- Animal stock feeds – cattle, horse, sheep, and poultry feed in 20–50 kg bags

- Agricultural products – bulk seeds, pulses, and grains for planting or wholesale supply

- Gardening and landscaping supplies – mulch, potting mix, soil conditioners, and fertilisers

- Specialty bulk foods – large-format rice, flour, or sugar bags for foodservice and export markets

In turnkey setups, the ADM-XL Series often pairs with:

- Bulk infeed systems (belt or screw conveyors)

- High-capacity weighers or volumetric fillers

- Dust extraction for cleaner operation

- Palletising systems for export-ready loads

This combination delivers a robust, high-throughput packaging line designed for reliability in even the most demanding environments.

Application Examples — ADM-XL Series

Example — 20 kg Stock Feed

Ideal for packaging 20 kg woven polypropylene bags of cattle, horse, sheep, or poultry feed. The ADM-XL can be paired with bulk belt infeeds, high-capacity weighers, and dust extraction units to ensure accurate filling and clean operation.

Typical results:

- Strong, reliable seals on heavy-gauge woven bags

- Accurate weight control for compliance and customer confidence

- Seamless integration with palletising for direct-to-distribution handling

- Reduced product spillage and improved operator safety

Example — 25 kg Fertiliser Bags

Well suited to running 25 kg laminated film bags of fertiliser, soil enhancer, or landscaping products for wholesale and export. The XL Series integrates with screw conveyor infeeds, bulk weighers, and automated palletisers for a streamlined packaging process.

Typical results:

- Consistent bag weights for large-scale production

- Strong seals to withstand stacking and export shipping

- Integration with dust control systems for a cleaner production environment

- High throughput without compromising seal quality

Specifications

| Model | ADM-XLi400 | ADM-XLi600 | ADM-XLi800 | |

| Motion | Intermittent | |||

| Environment | Suitable for dry and harsh environment | |||

| Construction | Mild Steel | |||

| Bag Type | Pillow, Block bottom | |||

| Bag Size | 120-400(W) x Up to 550(L) | 200 –600(W) x Up to 900(L) | 250-800(W) x Up to 1200(L) | |

| Speed | Up to 80bpm | Up to 40bpm | Up to 20bpm | |

| Power Supply | 415V, 50Hz, 5kW | 415V, 50Hz, 6kW | 415V, 50Hz, 7kW | |

| Air Pressure | 0.4cum/min, 0.6MPa | 0.5cum/min, 0.6MPa | 0.6cum/min, 0.6MPa | |

| Machine Dimension | 1560(W) x 2545(L) x 2230(H) mm | 1850(W) x 2880(L) x 2450(H) mm | 2150(W) x 3200(L) x 2850(H) mm | |

| Weight | 1200kg | 2000kg | 2500kg | |