Packaging Machinery

Industrial Linear Weighers. Belt Drive Weighers.Combination Weighers.

ADM Industrial Weighers form a critical part of modern packaging lines, ensuring every pack is filled with speed, consistency, and accuracy. Offered as part of ADM’s integrated range, these weighers are engineered for reliability and precision, helping food producers and manufacturers reduce giveaway, improve yield, and maintain the highest quality standards.

From high-speed multihead weighers for snacks and confectionery, to linear, screw-feed, and belt-drive models for powders, grains, fresh produce, and delicate items, ADM provides the right weighing solution for every product type. Seamlessly integrated with ADM’s DP series pouch fillers, VFFS baggers and turnkey lines, these weighers are supported by local expertise and service to keep production running at maximum efficiency.

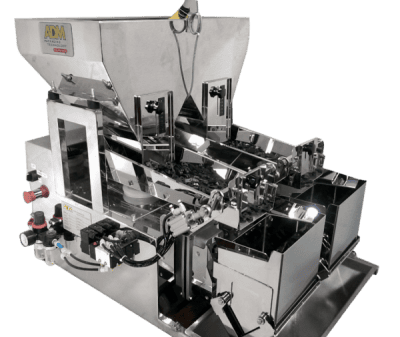

2 Head Linear Weigher

The ADM 2‑Head Linear Weigher is engineered for medium to large production runs, offering excellent weight accuracy and steady speeds. It finds its most effective use in automatic and semi-automatic packaging lines, frequently integrated into ADM’s DP3 series pouch fillers and XD20 models for seamless operation.

Constructed from hygienic stainless steel, the weigher is designed for reliability, ease of cleaning, and stable day-to-day performance. It comes in both vibration pan and belt-drive configurations to match a wide range of products from free-flow items like sugar, salt, or coffee beans to semi-flow items like diced vegetables or pitted dates. The weight range spans from 40 g up to 12 kg, depending on the selected model.

Key features include a high-precision digital load cell, intuitive touchscreen controls, and tool-free removal of weigh buckets and pans all wrapped in a stainless-steel housing designed for packaging environments. Functionally flexible and reliably accurate, the 2‑Head Linear Weigher is an efficient and adaptable weighing solution for diverse product types and production requirements.

- Hygienic stainless steel construction with good IP protection

- Multiple formats available—linear, belt, screw feed, and combination heads

- High-precision load cells for consistent fills

- Vacuum or Teflon pan options for product handling versatility

- Tool-free changeovers and easy clean-down access

- Optional modules: timing hoppers, angled chutes, printer/data output, dust-extraction

- Controls with recipe storage for multi-SKU operations

- Seamless integration into ADM VFFS, conveyors, and automated systems

Used across food, pharmaceutical, and industrial sectors:

- Snacks, confectionery, nuts — with linear or combination—weigh dosing

- Powders and spices — with screw feed or belt drive systems

- Fresh produce & wet applications — with washdown-compatible weigh modules

- Bulk powders & grains — with 2-head combination for accuracy at high volumes

Each model can be paired with ADM’s bagging, conveyors, inspection, and downstream systems for complete line integration.

Detailed Application

Example — Roasted Coffee Beans

A specialty coffee roaster requires a flexible dosing solution for 250g up to 1kg with future option to pack 2 kg bags of roasted beans. By integrating a linear weigher with smooth, angled pans, the system achieves:

- Accurate fills across a wide size range — from small retail packs to larger wholesale bags

- Gentle product handling that maintains bean integrity and minimises breakage

- Fast changeovers between bag formats such as pillow, gusseted, and block-bottom

- Data recording and traceability for each batch, supporting quality assurance and export compliance

The weigher integrates seamlessly with ADM-DP31 Coffee pouch filler to produce consistent, retail ready packs with strong seals, extending freshness and presentation quality for supermarket and café supply

Specifications

| Model | ADM-MX2.2-5L- Vib | ADM-MX2.2-8L- Vib | ADM-MX2.2-16L- Vib | ADM-MX2-25L-Vib |

| Range | 40-3000 g | 40-3000g | 400-12000g | 400-12000 g |

| Accuracy | 0.5-3 g | 0.5-6g | 1-10 g | 1-10 g |

| Speed | 10-32 wpm | 10-32 wpm | 10-20 wpm | 10-20 wpm |

| Volume max | 5000 ml | 8000 ml | 16000 ml | 25000 ml |

| Programs | 99 | |||

| Power | 800W | 800W | 1200W | 1200W |

| Power supply | 240V, 50Hz, 4A | 240V, 50Hz, 3A | 240V, 50Hz, 7A | 240V, 50Hz, 6A |

| Machine Size mm | 890L, 760W, 1070H | 890L, 760W, 1220H | 1050L, 1060W, 1160H | 1050L, 1060W, 1260H |

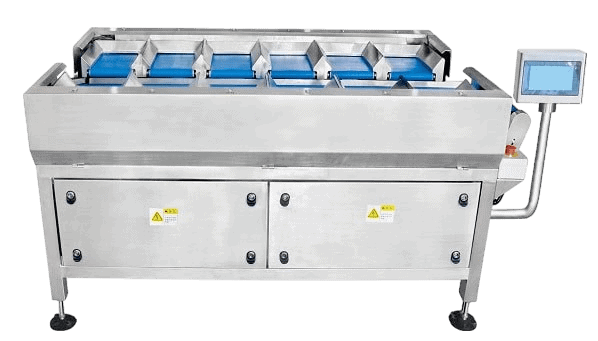

10 Head Combination Weigher

The ADM 10‑Head Combination Weigher is an exceptional balance of precision and value. It’s a popular choice for production plants managing a wide variety of SKUs and runs of medium length—delivering reliable weight accuracy at reasonable speeds.

Built for versatility, this weigher features stainless steel construction, designed to be robust, easy to clean, and compatible with ADM’s packaging machinery. It comes equipped with vibration-type feeders for free-flow items—like sugar, rice, powder, or diced vegetables—as well as optional screw feeders for more challenging products such as diced meat or poultry. The staggered bucket dump system helps maintain speed and accuracy while minimising product giveaway.

With bucket volumes of 2.6 L or 5.6 L, the weigher accommodates both small and larger portions, handling weights from 10 g to 5,000 g depending on model. Its user-friendly design enables fast cleaning, easy access, and seamless integration into ADM’s turnkey systems, such as VFFS machines, pouch fillers, jar fillers, conveyors, and inspection systems.

- 10 weigh heads with staggered dumping for high-accuracy portioning

- Available bucket sizes: 2.6 L and 5.6 L, with optional dimpled surfaces

- Stainless steel frame with good IP rating, easy-to-clean design

- Vibration feeder for free-flow products; screw feeder for difficult-to-feed items

- User-friendly 10.4″ touchscreen interface with recipe storage

- Optional modules: timing hopper, printer output, Teflon coating, angled pans

Ideal for markets where consistent weight accuracy and versatility are key, including:

- Free-flow powders and granules: sugar, rice, coffee, spices

- Processed dry foods: snacks, cereals, grated cheese, diced vegetables

- Non-food: fasteners, plastic components, hardware parts

Typically integrated with ADM VFFS machines and pouch fillers to create streamlined packaging lines.

Example — Mixed Snack Packs

A snack producer can portion multiple SKUs nuts, dried fruit, and chips into accurately weighted packs using one machine. The ADM 10-Head Combination Weigher offers:

- Precise multi-flavor dosing within ±1 g accuracy for balanced snack mixes

- Smooth transitions between product SKUs with stored recipe recall

- Compact integration with baggers and conveyors for high-speed throughput

- Gentle handling options (dimpled or coated buckets) to maintain product quality

Specifications

| Model | ADM-MA10-2.6L | ADM-MA10-5.6L |

| Weighing Range | 10-1500 g (3000g max) | 10-3000 g (5000g max) |

| Weighing Accuracy | 0.1 – 1.5 g | 1 – 10 g |

| Speed | Up to 70 Bags/min | Up to 50 Bags/min |

| Bucket Volume | 2.6 Litre | 5.6 Litre |

| Preliminary Program | 99 Sets | |

| Display Screen | 10.4 inch touch screen | |

| Power supply | 240V , 50Hz, 1500W | 240V , 50Hz, 2000W |

| Optional – Dimple | ADM-MA10D-2.6L | ADM-MA10D-5.6L |

| Optional | Timing Hopper / Rotary top cone / Printer | |

14 Head Combination Weigher

The ADM 14‑Head Combination Weigher is the most widely adopted scale in our weighers range, trusted across Australian manufacturing plants for its reliability through long production runs. Ideal for operations with diverse SKUs, this weigher offers high-speed accuracy even when handling a wide variation of product types and sizes.

Built for demanding environments, the unit features a robust stainless-steel construction with good IP rating, ensuring longevity under both dry and washdown conditions. Its user-friendly HMI allows recipes to be stored individually or managed via PID control, enabling easy reuse across product runs.

With both vibration feeders for free-flow items such as sugar, rice, coffee, or diced vegetables—and screw feeders for more challenging products like diced meat, the weigher offers exceptional versatility. Designed for integration, it pairs seamlessly with ADM’s VFFS, pouch filler, and HFFS systems to form efficient, turnkey packaging lines.

- High-speed, 14-head configuration for rapid portioning

- Robust stainless steel design with easy-clean PHSA panels

- Vibration feeder commonly used; optional screw drive for sticky or irregular products

- Integrated recipe storage for fast changeovers

- Designed for turnkey integration with VFFS, pouch fillers, and checking systems

High-performance choice for:

- Free-flow powders & granular goods such as sugar, rice, coffee, seasoning blends

- Diced or mixed foods including vegetables, cheese, snack mixes

- Wet or sticky products like marinated meats, poultry, or cheese (when fitted with screw feeders)

- Non-food items such as pharmaceutical tablets or hardware components

Example — Mixed Snack Packs

A snack producer can portion mixed SKUs—nuts, dried fruit, chips—accurately into different retail pack sizes. The ADM 14-Head Combination Weigher provides:

- Fine-tuned dosing accuracy across multiple blend recipes

- Fast SKU changeovers using recipe memory

- Seamless downstream integration into bagging and inspection systems

Example — Frozen Vegetable Portions

For high-volume frozen IQF vegetables, the 14-Head Weigher delivers:

- Gentle vibratory feeding with minimal product damage

- Consistent weight accuracy despite variable densities and temperatures

- Washdown-compatible design for cold-room and hygiene compliance

Specifications

| Model | ADM-MA14-2.6L | ADM-MA14-5.6L |

| Weighing Range | 10-2000 g (3000g max) | 10-3000 g (5000g max) |

| Weighing Accuracy | 0.1 – 1.5 g | 1 – 10 g |

| Speed | Up to 120 Bags/min | Up to 70 Bags/min |

| Bucket Volume | 2.6 Litre | 5.6 Litre |

| Preliminary Program | 99 Sets | |

| Display Screen | 10.4 inch touch screen | |

| Powers Supply | 240V , 50Hz, 1800W | 240V , 50Hz, 2200W |

| Optional – Dimple | ADM-MA14D-2.6L | ADM-MA14D-5.6L |

| Optional | Timing Hopper / Rotary top cone / Printer | |

16 Head Combination Weigher

The ADM 16‑Head Combination Weigher is engineered for peak performance in fast-paced packaging environments, such as continuous-motion VFFS, HFFS systems, or when feeding dual packers simultaneously. Unique to this model, the unit can also operate as two separate 8-head weighers ideal when creating two different blends or dividing production between lines. It features a sophisticated three-level bucket system with memory-level capability and a springless design, resulting in enhanced weight precision and faster throughput.

Built from modular stainless steel, it’s easy to maintain and performs reliably in demanding environments. Featuring vibration-type feeding, it handles products from free-flowing grains like sugar and coffee beans to mixed nuts and oats. The weigher integrates effortlessly with ADM’s full range of packaging systems VFFS, pouch fillers, conveyors making it a true workhorse in turnkey solutions.

- High-speed 16-head configuration designed for continuous-motion and dual-line packaging

- Dual operation mode: can function as two independent 8-head systems

- Three-level memory bucket system for improved accuracy and speed

- Springless bucket mechanism enhances precision and consistency

- Vibratory feeder optimal for free-flow solids such as grains and dry snacks

- Modular stainless steel construction for durability and easy sanitation

- Seamless compatibility with ADM bagging, inspection, and downstream automation

Ideal for industries requiring speed, accuracy, and versatility, including:

- Free-flow bulk ingredients: sugar, rice, coffee beans, seasoning mixes

- Dry food products: nuts, granola, cereal, grated cheese

- Processed blends: snack mixes, pet food, dried vegetables

- Pick-and-mix or dual-product batching when operating dual 8-head mode

Typical deployment includes seamless integration with VFFS, pouch fillers, and inspection systems.

Specifications

| Model | ADM-MX16.2-0.5L | ADM-MX16.4-1.6L |

| Weighing Range | 10-200g | 10-1000g |

| Weighing Accuracy | 0.5 | 0.1 – 1.5 g |

| Speed | 2×90 ppm (180ppm) High Speed with Memory level | |

| Bucket Volume | 0.5 Litre | 1.6 Litre |

| Preliminary Program | 99 Sets | |

| Display Screen | 10.4 inch touch screen | |

| Power supply | 240V, 50Hz, 2000W | 240V, 50Hz, 1200W |

| Optional – Dimple | ADM-MX16.2D-0.5L | ADM-MX16.6D-1.6L |

| Optional | Timing Hopper / Rotary top cone / Printer | |

20 Head Combination Mixing Weigher

The ADM 20-Head Combination Mixing Weigher is designed for high-throughput lines that need precise multi-component mixes at speed. Its 20 heads can be configured as two independent 10-head groups (or other groupings) to dose different ingredients simultaneously, then combine them to a target ratio before discharge. This architecture helps control recipe accuracy, minimise giveaway, and keep pace with fast packaging machines.

Stainless-steel construction, modular buckets, and easy-clean product contact parts support hygiene and quick changeovers. High-sensitivity load cells and advanced combination algorithms select the optimal head set on each cycle, maintaining consistent weights across single-product and multi-product blends. The system integrates smoothly with ADM baggers (VFFS/HFFS), pouch fillers, and downstream inspection, forming the core of a turnkey, recipe-driven mixing and packing line.

- 20-head multihead design for high-speed portioning and mixing

- Group configuration (e.g., 2×10 heads) for multi-ingredient dosing and ratio control

- Recipe management with target % ratios per component

- High-accuracy load cells with intelligent combination selection to reduce giveaway

- Flexible product handling: smooth, dimpled, or coated contact parts; timing hopper options

- Fast changeovers with tool-free access to contact parts and buckets

- Stainless-steel build with easy-clean design for hygiene-critical environments

- Integration-ready with ADM VFFS/HFFS, pouch and cup/jar fillers, conveyors, and inspection

Ideal when you need to blend multiple components at speed while holding tight weight and ratio tolerances:

- Snack mixes & trail mix (nuts, seeds, dried fruit, inclusions)

- Frozen veg blends (peas/corn/carrots, specialty mixes)

- Pet food blends (kibble + treats / functional inclusions)

- Confectionery assortments (mixed lollies or coated pieces)

- Cereal & granola mixes (flakes, clusters, fruit pieces)

Often paired with ADM baggers and checkweighers for closed-loop control and consistent pack quality.

Example -Component Snack Mix (Ratio Control)

A producer requires accurate blending of almonds, cashews, raisins, and choc pieces into retail packs at fixed ratios (e.g., 35/35/20/10). The 20-head mixing weigher assigns head groups per ingredient and combines weighments to the target recipe before discharge.

Typical capability:

- Tight ratio control across components at target pack weight

- High throughput using parallel head groups with a timing hopper

- Reduced giveaway via intelligent combination selection

Fast recipe changeovers with stored ratio presets and contact-part swaps

Specifications

| Model | ADM-MT20-1.6L | ADM-MT20-2.6L |

| Weighing Range | 10-1000g (single dose), 20-2000g (mixing dose) | |

| Weighing Accuracy | 0.5g | |

| Speed | 70 bpm (mixing), 140 bpm (single) | |

| Bucket Volume | 1.6 Litre | 2.6 Litre |

| Preliminary Program | 99 Sets | |

| Display Screen | 10.4″ touch screen | |

| Power supply | 240V , 50Hz, 2000W | |

| Optional – Dimple | ADM-MT20D-1.6L | ADM-MT20D-2.6L |

| Optional | Timing Hopper / Rotary top cone / Printer | |

32 Head Combination Mixing Weigher

The ADM 32-Head Combination Mixing Weigher is engineered for ultra-high-speed mixing and portioning in high-volume production environments. Its 32 heads deliver exceptional throughput, capable of feeding fast lining systems or running complex blends using ingredient grouping logic. The unit is fitted with high-resolution load cells, advanced combination algorithms, and a user-friendly interface with multi-recipe storage, making it ideal for multi-component mixes requiring precision and speed.

Modular stainless-steel construction ensures durability and easy sanitation. The design supports easy changeovers and integrates perfectly with ADM’s VFFS, pouch filler, and downstream automation systems, forming the backbone of truly turnkey mixing and packaging solutions.

- 32 independently programmable heads for simultaneous multi-component weighments

- Ingredient grouping and ratio control for precise mix compliance

- High-speed dispensing with intelligent combination optimization to reduce giveaway

- Modular stainless-steel design for easy cleaning and maintenance

- Compatible with multiple feeding options (vibration, screw, timing hoppers)

- Touchscreen interface with recipe memory and fast setup

Integration with ADM packaging systems for full line automation

Perfect fit for mass-market mixer lines in sectors such as:

- Snack assortments and trail mixes (nuts, seeds, raisins, chocolate)

- Frozen vegetable blends (corn/peas/carrot mixes)

- Cereal and granola formulations (flakes, clusters, fruit bits)

- Pet food with functional blend additions (kibble, vitamins, coatings)

- Confectionery batch blends (fruit candies, lollies in blends)

Typically paired with ADM baggers, weighing, and processing conveyors to build efficient, high-throughput packaging lines.

Example — Premium Trail Mix Blend (Multi-Ingredient Ratio Control)

A snack manufacturer requires precise doses of almonds, peanuts, dried fruits, and chocolate pieces in a 40/30/20/10 ratio into 500 g packs.

The 32-Head weigher, using head grouping, delivers:

- Correct ratios across multiple ingredients with high repeatability

- Clean ingredient separation using timing hoppers

- Rapid recipe changeovers between blends

- High throughput matched to VFFS throughput

Specifications

| Model | ADM-MA32-0.5L |

| Weighing Range | 5-240g |

| Weighing Accuracy | 0.5g |

| Speed | 60 BPM (mixing) |

| Bucket Volume | 0.5 Litre |

| Preliminary Program | 99 Sets |

| Display Screen | 10.4″ touch screen |

| Power supply | 240V , 50Hz, 1800W |

| Optional – Dimple | ADM-MA32D-0.5L |

| Optional | Timing Hopper / Rotary top cone / Printer |

Bench Weigher

The ADM Bench Weigher is designed as a reliable solution for manual or semi-manual weighing in environments where products—such as meat, poultry, fish, or other uniquely shaped items—aren’t suited to high-speed automated weighing systems. The unit comes in two configurations:

- Static Bench Type: Operators manually place products into the weigh pan for rapid weighing and tip-out once the desired weight is reached.

- Belt Drive Feeder: A gentle, continuous feed system suited to cumbersome or delicate products.

With stainless steel construction, high-precision load cells, and intelligent multiple sampling and fault detection modes, this weigher delivers accurate and efficient results even when constant scale monitoring isn’t practical. Its ergonomic design—featuring a well-placed working height—enhances user comfort and productivity. RFID recipe storage, programmable tare functions, and part-counting capabilities add to its versatility and ease of use.

- Hygienic stainless-steel build for food-safe environments

- Dual formats: static bench or belt-drive feeder

- High-precision load cells with intelligent multiple weighing algorithms

- Auto fault-alarm system to minimise downtime

- Operator-friendly 10.4″ touchscreen interface

- Counting mode available by setting standard weight

- Tool-free, easy-detach components for fast hygiene compliance

Stable performance with enhanced productivity for both manual and semi-automated setups

Ideal for packaging that falls outside the scope of automatic lines, such as:

- Uneven or fragile food items: meat, poultry pieces, fish fillets

- Batch packaging of irregular products like artisan cheeses or bakery items

- Counting-based scenarios: portion control on trays, or ingredient verification

- Situations needing manual oversight, but with improved speed and efficiency

Often implemented in low-volume or niche packaging lines, the Bench Weigher becomes a practical, accurate asset where flexibility is essential.

Example — Manual Meat Portioning

An artisanal meat producer regularly packs uneven cuts into trays where automatic dosing fails. The static bench weigher allows operators to quickly place portions in the pan until they reach target weight, delivering:

- Fast portioning without need for constant monitoring

- Versatile handling of awkward shapes and variable sizes

- Improved accuracy over ordinary manual scales

- Enhanced operator ergonomics and reduced physical strain

Specifications

| Model | ADM-MBV-14.2-2.5L- Vib | ADM-MBB-12.2-2.5L- Belt |

| Weighing Range | 10-1500g | 10-1500g |

| Weighing Accuracy | 0.5-5g | 0.5 – 5 g |

| Max Combined Weight | 6000g | 6000g |

| Speed | 30ppm | 30ppm |

| Bucket Volume | 2.5L | 2.5L |

| Preliminary Program | 99 Sets | |

| Display Screen | 10.4 inch touch screen | |

| Power supply | 240V, 50Hz, 2000W | 240V, 50Hz, 1200W |

| Optional – Dimple | ADM-MBV14.2D-2.5 | ADM-MBB12.2D-2.5 |