Product Handling

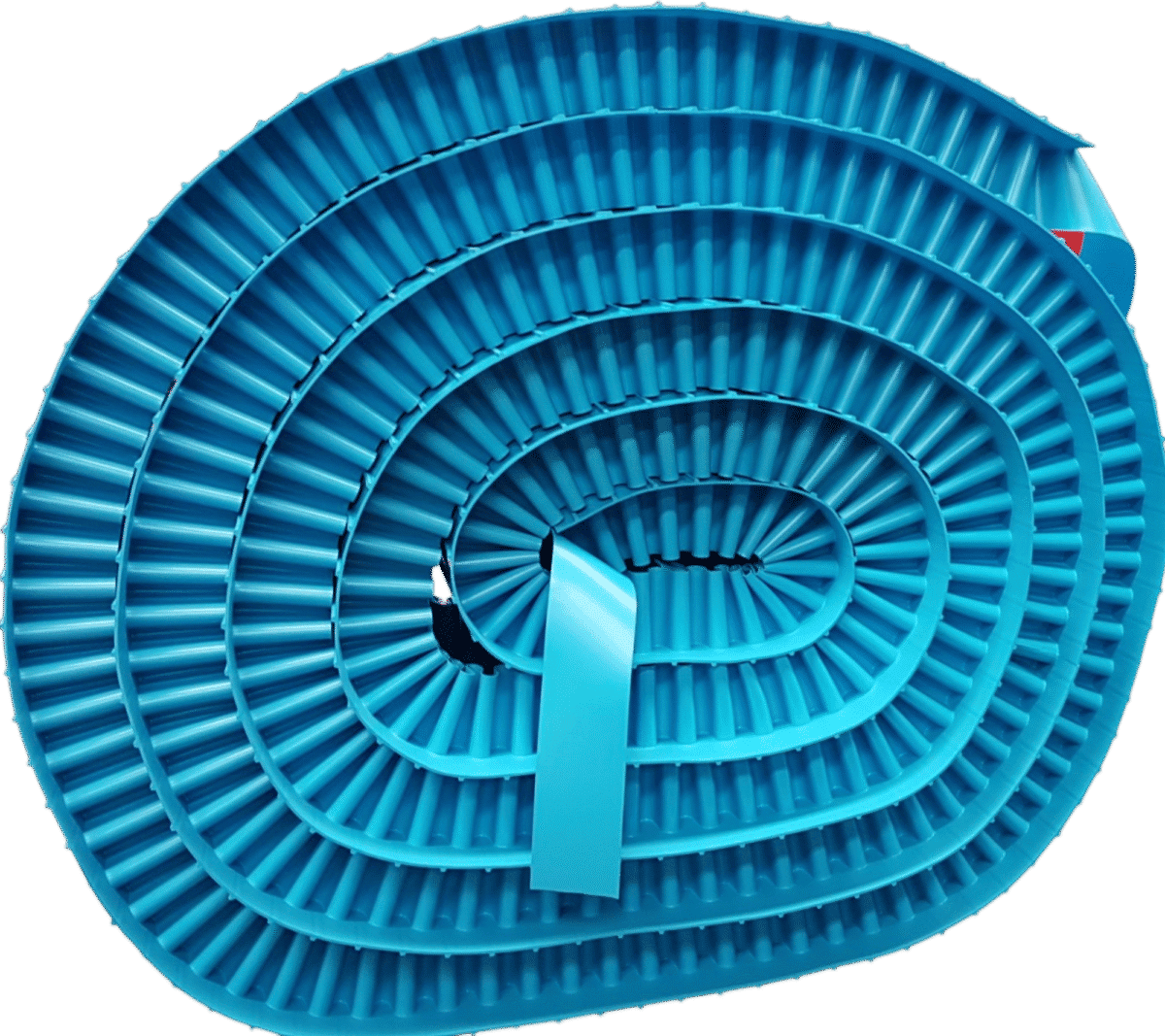

ThermoDrive Belt Conveyor

ADM’s ThermoDrive Belt Conveyor combines hygienic design, robust construction, and smooth belt operation to offer a superior conveying solution for food manufacturers. Unlike traditional modular or flat belts, ThermoDrive belts offer positive-drive operation that minimises belt slippage and tensioning issues, reducing maintenance and sanitation time.

But the real power of the ThermoDrive system lies in how it supports turnkey automation seamlessly integrating into full packaging lines where hygiene, product integrity and uptime are non-negotiable.

ADM’s ThermoDrive Belt Conveyor is a high-performance, food-grade conveying system purpose-built for manufacturers who require clean, reliable, and fully integrated material handling. Engineered with a positive-drive, solid thermoplastic belt, this system overcomes the limitations of traditional flat or modular belts by eliminating slippage, tracking issues, and bacterial harbour points—making it ideal for FSANZ-compliant operations, HACCP-certified plants, and high-care hygiene zones where food safety is critical.

Designed for demanding environments, the ThermoDrive conveyor supports washdown operations, withstands aggressive cleaning chemicals, and maintains structural integrity during frequent sanitation cycles. Its one-piece belt design allows for tool-less removal and rapid cleaning, reducing downtime and helping facilities meet stringent Australian food safety standards with ease.

Whether you’re handling shredded cheese, cooked meats, frozen vegetables, ready meals, or snack products, the ThermoDrive conveyor ensures consistent product flow, minimal breakage, and clean transfer between processing and packaging stages. It can be configured for horizontal or inclined transport, customised with cleats or side guards, and fitted with smart level sensors to enable start-stop control based on upstream and downstream demand.

More than just a conveyor, the ThermoDrive becomes a critical link in ADM’s turnkey packaging systems—seamlessly connecting with multihead weighers, VFFS machines, metal detectors, and end-of-line equipment. Every unit is tailored to fit your line layout, throughput targets, and integration requirements, giving you a fully harmonised solution backed by ADM’s project delivery expertise.

- Australian made

- Fully Stainless-Steel Construction

- Hygienic, One-Piece Belt Design

- Scoop flights, corrugated sidewall and bucket elevator type conveying

- Integrated wash-down system (CIP) to clean both sides of the belt

- Customised Angles and Heights

- Easy belt release for inspection

- Interlocks installed for safety

- Cold environment conveyors

- Customised Angles and Heights

- Compact, Modular Frame Design

- Integrated Level Control and Sensors

- Designed for Australian food manufacturing compliance

- CIP (Clean in place) FULL WASHDOWN SYSTEM option (See video)

- USDA/FDA compliant materials

Shredded Cheese

Transfers product from dicer to weigher or VFFS

Prevents clumping and breakage

Hygienic design suited for dairy environments

Cooked & Processed Meats

Handles diced or sliced meats into tray sealers or weighers

Smooth belt resists buildup from oils and marinades

Withstands heavy washdown and sanitation cycles

Fresh Produce

Gently conveys leafy greens or cut fruit

Custom cleats and guides for delicate products

Tool-less belt removal for quick cleaning between batches

Frozen Foods

Moves IQF vegetables, patties, or frozen meals post-freezer

Maintains performance in low-temperature environments

Integrates with weighers and packaging machines

Optional high-load configurations for heavier items

Detailed Application Example: Dairy & Cheese

ADM’s ThermoDrive Belt Conveyor is designed for high-care dairy environments where hygiene, efficiency, and consistent product handling are essential. Whether you’re packaging shredded, sliced, cubed, or block cheese, this conveyor ensures clean and reliable transfer between processing and packaging stages.

Its solid, positive-drive thermoplastic belt eliminates slippage, reduces sanitation time, and avoids the product build-up often seen in modular belt systems. Combined with a sloped, stainless-steel frame and tool-less belt removal, it’s built for FSANZ and HACCP-compliant operations requiring frequent washdowns and allergen control.

Commonly integrated after shredders or de-clumpers, the ThermoDrive smoothly feeds into weighers, auger fillers, or VFFS machines. Belt cleats or side guides can be added to maintain steady product flow—essential for accurate filling and minimal giveaway.

An optional Clean-in-Place (CIP) system is available for fully automated internal cleaning. Spray bars target the belt and frame to reduce manual labour and speed up changeovers—ideal for multi-product or allergen-sensitive lines.

Key Benefits:

Hygienic design for dairy-grade washdowns

Smooth product flow improves weighing and filling

Custom configurations for cleats, guides, or incline

Easily integrates into complete ADM packaging systems

Specifications

| Model | ADM-MCV |

| Hopper opening size | 1400 x 1400 mm |

| Capacity | 200kg power sieve (sultanas), 50kg lower feed hopper |

| Feed rate | 60kg/min max (sultanas) |

| Speed | 1800 rpm max |

| Power Supply | 415V, 50Hz, 1.1kW |

| Footprint inc platform | 2900L x 2200W x 2400H mm |