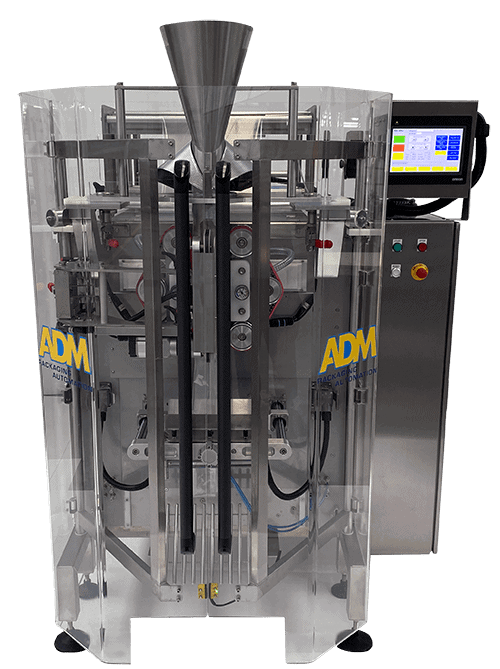

ADM-i Series VFFS Intermittent Motion Vertical Wrappers

The ADM-i Series is our precision-engineered family of intermittent motion vertical form fill seal (VFFS) machines, designed and built in Australia to deliver exceptional seal integrity and flexible packaging capability for a wide range of products and bag formats.

Where continuous motion VFFS machines keep the film moving during sealing, the i Series pauses the film for each seal cycle. This allows longer dwell times, making it ideal for heavier bags, difficult films, and products that demand extra-strong, reliable seals — including recyclable and compostable materials.

Placed at the heart of an ADM turnkey packaging line, the i Series integrates seamlessly with weighers, fillers, conveyors, inspection systems, case packers, and palletisers. The result is a versatile, high-precision packaging system that delivers consistent quality, minimal waste, and dependable operation shift after shift.

Engineered and built in-house in Australia, the i Series can be tailored to match your exact production needs — from bag style and size to product handling requirements and plant layout. Every machine leaves our factory ready to perform at world-class standards from day one, backed by the advantage of local manufacturing expertise and fast-response service support.

ADM-i260

ADM-i400

The ADM-i Series Intermittent Motion Vertical Form Fill Seal Machines are the result of over 30 years of Australian packaging engineering, built to deliver precision sealing, flexibility, and durability for an extensive range of bag sizes and products. Manufactured in ADM’s Thomastown facility, every i Series model combines robust stainless-steel construction, accurate film control, and operator-friendly design to produce consistent, retail-ready packaging.

What makes the i Series different is intermittent motion sealing technology. Instead of sealing while the film moves, the i Series pauses the film for each cycle, allowing:

- Longer sealing dwell times for stronger, more reliable seals on all film types

- Enhanced seal integrity on heavy bags and challenging materials

- Greater versatility for multiple bag styles, including pillow, gusseted, block-bottom, and quad-seal

- Compatibility with laminated, recyclable mono-material, and compostable films

- Consistent performance on thick or multi-layer laminates

ADM-i260 VFFS Compact, High-Output Performer

The ADM-i260 is optimised for small-format retail packs making it ideal for snacks, nuts, confectionery, and other lightweight products. Its compact footprint suits space-limited facilities, while delivering outstanding seal quality and reliable output.

Key advantages of the i260:

- Compact design without sacrificing performance

- Quick changeovers for multiple SKUs

- Accurate and consistent film tracking

- Seamless integration with weighers and inspection systems

ADM-i400 VFFS Mid-Range, Multi-Format Flexibility

The ADM-i400 handles medium-sized packs from medium to large bags, accommodating a variety of bag styles. It’s a versatile choice for producers needing flexible formats and strong seal performance across multiple product lines, from dry foods to roasted coffee beans.

Key advantages of the i400:

- Wide format range with multiple bag style options

- Precision dosing through integration with weighers, augers, or volumetric fillers

- Strong, airtight seals for freshness and shelf life

- Easy cleaning for allergen control and product changeovers

ADM-i600 VFFS Large-Format Heavy-Duty Specialist

The ADM-i600 is engineered for bulk packaging from 10–30 kg plus, making it ideal for wheat grain, pulses, large-format pet food, and other heavy-duty applications. Its reinforced sealing system and structural build provide maximum reliability in demanding environments.

Key advantages of the i600:

- Handles heavy-gauge laminated or woven polypropylene bags

- Reinforced sealing jaws for thick films and large pack sizes

- Accurate weighing and filling for export and domestic bulk supply

- Seamless integration with bulk infeed, dust control, and palletising systems

Features

- MADE IN AUSTRALIA

- Inflatable rewind air shaft

- Film unwind drive control

- Servo Motor Controlled Film Pull Belts

- Servo Motor Controlled Jaw Seal Actuation

- Panasonic Touch Screen Operator Interface

- Panasonic PLC – Based Control System

- Ethernet/IP Central Control system

- SMC Pneumatics Advanced Integration

- Vacuum Belt Drive

- Pneumatic balancing

- Safety Guarding and Interlocks to AS4024

Optional Elements

- Pillow bags

- Gusseted device

- Block Bottom bags

- Quadseal with middle seal

- Doy

- Zip applicator

- Nitrogen gas flush systems

- Hole punch (Round or Euro)

- Vacuum assist units

- Static eliminators

- Special End-Seal Configuration

- Vacuum seal

- Impulse seal

- Continuous seal

- String bags

ADM-i260 Compact FMCG Performer

Designed for small-format retail packs where seal integrity and presentation are critical, the i260 thrives in FMCG environments that require high output from a compact footprint. Its intermittent motion sealing provides extra dwell time for strong, consistent seals – even on challenging recyclable or compostable films.

Common applications include:

- Snacks and confectionery – nuts, chocolate pieces, dried fruit

- Dairy – grated cheese and shredded cheese with anti-caking powder dosing

- Coffee and dry ingredients – ground coffee, protein powders, spice blends

- Portion-controlled retail grains and pulses

In turnkey setups, the i260 integrates with multihead weighers for precise dosing, metal detectors for safety, and compact case packing solutions – delivering dependable performance in busy, space-limited facilities.

ADM-i400 Versatile Mid-Range Specialist

Perfect for medium-sized packs where flexibility and seal strength go hand in hand, the i400 is a go-to for producers running multiple formats and products. Its ability to handle pillow, gusseted, block-bottom, and quad-seal bags makes it a strong choice for premium retail and foodservice applications.

Common applications include:

- Cereals, muesli, and grains – 1 kg to 10 kg packs

- Rice, pasta, and pulses – for retail and wholesale

- Roasted coffee beans – 1, 2, and 3 kg block-bottom or quad-seal bags with gas flushing

- Foodservice dry mixes – flour, baking blends, seasonings in mid-size bags

In ADM turnkey lines, the i400 often pairs with weighers or auger fillers for dosing, MAP systems for extended shelf life, and automated boxing or palletising – delivering presentation and performance in one package.

ADM-i600 Large-Format Heavy-Duty Specialist

Built for bulk and industrial packaging, the i600 is engineered to manage the challenges of heavy weights, large bag sizes, and demanding materials. With reinforced sealing jaws and heavy-duty construction, it provides dependable operation for export-ready and domestic bulk supply.

Common applications include:

- Wheat grain – 10–30 kg woven polypropylene or laminated film bags

- Large-format pet food – premium kibble in pallet-ready export bags

- Specialty agricultural products – seeds, legumes, and animal feed supplements

- Industrial dry ingredients – sugar, salt, or granulated products for manufacturing

Turnkey integration for the i600 typically includes bulk infeed conveyors, high-capacity weigh hoppers, dust control, and automated palletising – creating a line ready to handle weight, volume, and compliance from start to finish.

Detailed Application

Example – Snack Nuts with the ADM-i260

Nut processors requiring a reliable bagging solution for 100–500 g pillow or gusseted bags. The ADM Intermittent Motion VFFS can be paired with your existing multihead weigher or supplied as part of a complete ADM turnkey solution. The result you can expect:

- Consistent sealing quality even with oil-coated or seasoned products

- Efficient changeovers between pack sizes and product varieties

- Gentle film handling to reduce material waste

- Compliance with FSANZ hygiene and food safety requirements

Example – Roasted Coffee Beans with the ADM-i400

Specialty coffee roasters requiring a premium packaging solution for 1 kg, 2 kg, and 3 kg block-bottom or quad-seal bags. The ADM-i400 can be paired with a multihead weigher, valve applicator, and gas flushing for extended shelf life. The result:

- Strong, airtight seals to preserve aroma and freshness

- Professional block-bottom or quad-seal presentation for retail or wholesale

- Consistent bag dimensions for efficient boxing and palletising

- Rapid changeovers between bag sizes with stored machine recipes

Rapid changeovers between bag sizes with stored machine recipes

Example – Muesli & Cereal with the ADM-i400

Breakfast cereal and muesli producers requiring a versatile bagging machine for 250 g to 1 kg packs. The ADM Intermittent Motion VFFS can be integrated into an existing dry product line or supplied with upstream product handling equipment for a turnkey system. The result:

- Accurate fills through integration with high-precision weighing systems

- Flexible bag style options including pillow, gusseted, and block-bottom

- Easy cleaning for allergen control between product runs

- Shelf-ready packs with strong branding presence

Example – Wheat Grain with the ADM-i600

A bulk grain supplier requiring a durable, high-capacity packaging solution for 10–30 kg wheat grain bags. The ADM-i600 can be integrated into a bulk handling line with infeed conveyors, weigh hoppers, dust control, and automated palletising. The result:

- Strong seals on heavy-gauge laminated or woven polypropylene bags

- Consistent bag weight accuracy for export and domestic distribution

- Smooth product flow with minimal grain breakage

- Seamless integration with storage silos, conveying systems, and palletising equipment

Specifications

| Model | ADM-i260 | ADM-i400 | ADM-i600 | |

| Motion | Intermittent | |||

| Environment | Suitable for dry and wet areas (Option) | |||

| Construction | Stainless Steel | |||

| Bag Type | Refer above optional features | |||

| Bag Size | 60-260(W) x Up to 300(L) | 120-400(W) x Up to 550(L) | 200 –600(W) x Up to 900(L) | |

| Speed | Up to 100bpm | Up to 80bpm | Up to 40bpm | |

| Power Supply | 415V, 50Hz, 4kW | 415V, 50Hz, 5kW | 415V, 50Hz, 6kW | |

| Air Pressure | 0.3cum/min, 0.6MPa | 0.3cum/min, 0.6MPa | 0.3cum/min, 0.6MPa | |

| Machine Dimension | 1320(W) x 2170(L) x 1920(H) mm | 1560(W) x 2545(L) x 2230(H) mm | 1850(W) x 2880(L) x 2450(H) mm | |

| Weight | 1200kg | 1600kg | 2000kg | |